Our approach: mastering the entire industrial traceability value chain

At CIPAM, we are convinced that industrial performance requires a global, integrated and sustainable vision of identification, traceability and digitalization systems. That's why we structure our support around five main complementary areas of expertise, covering the entire lifecycle of your data: from field identification to strategic valorization, via collection, integration and follow-up. Whether you're in manufacturing, logistics, healthcare, railways, the environment or the automotive industry, we work with you to design tailor-made, reliable and interconnected solutions, with a focus on return on investment. Explore each of our areas of expertise to discover how we can help you transform your operations with robust technologies, intelligent software and long-term support.

Identify assets and flows

Identification is the starting point of any traceability approach. It enables a unique, reliable and durable identity to be assigned to each product, part or piece of equipment, making it easier to track them throughout their life cycle. Whether for critical components, reusable containers, finished products or production batches, CIPAM deploys the technologies best suited to your industrial environment: RFID (UHF, HF, NFC), barcodes, 2D Datamatrix, DPM engraving or laser marking.

Our experts will help you choose the right substrate, the right label material and the most appropriate identification technology to meet your requirements (heat, humidity, abrasion, industry regulations, etc.). Good identification is the key to robust, automated traceability that is interoperable with your information systems. It is the first building block in your industrial digitalization chain.

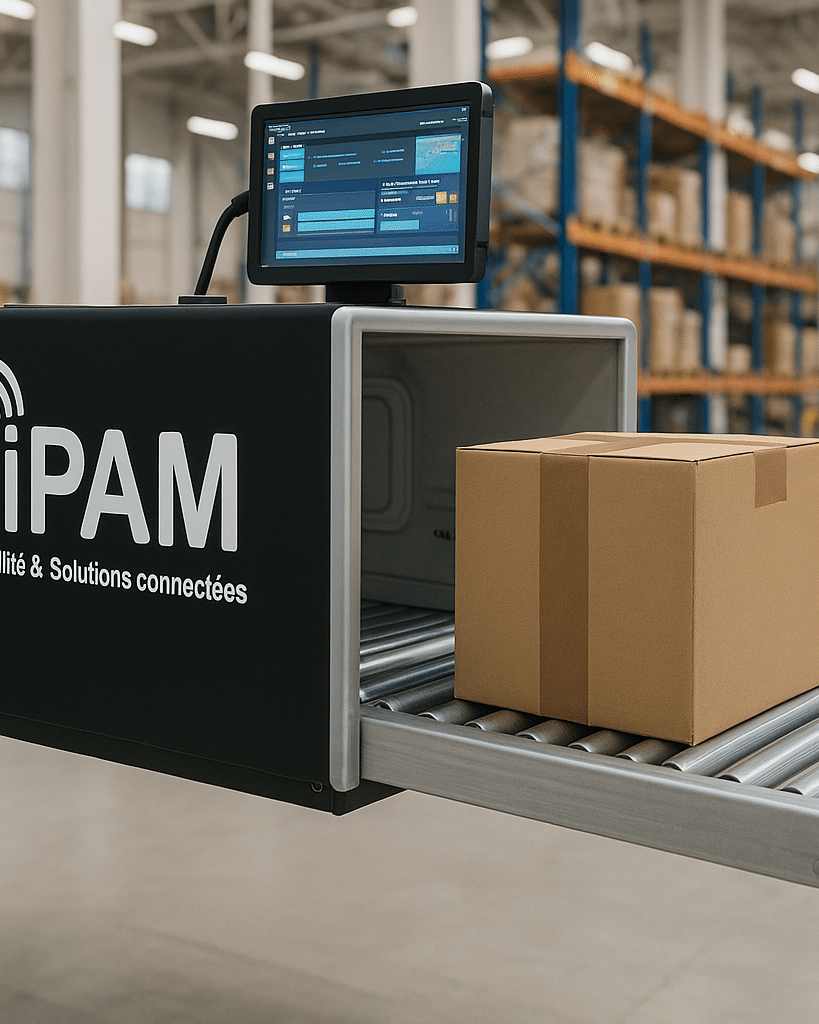

Data acquisition

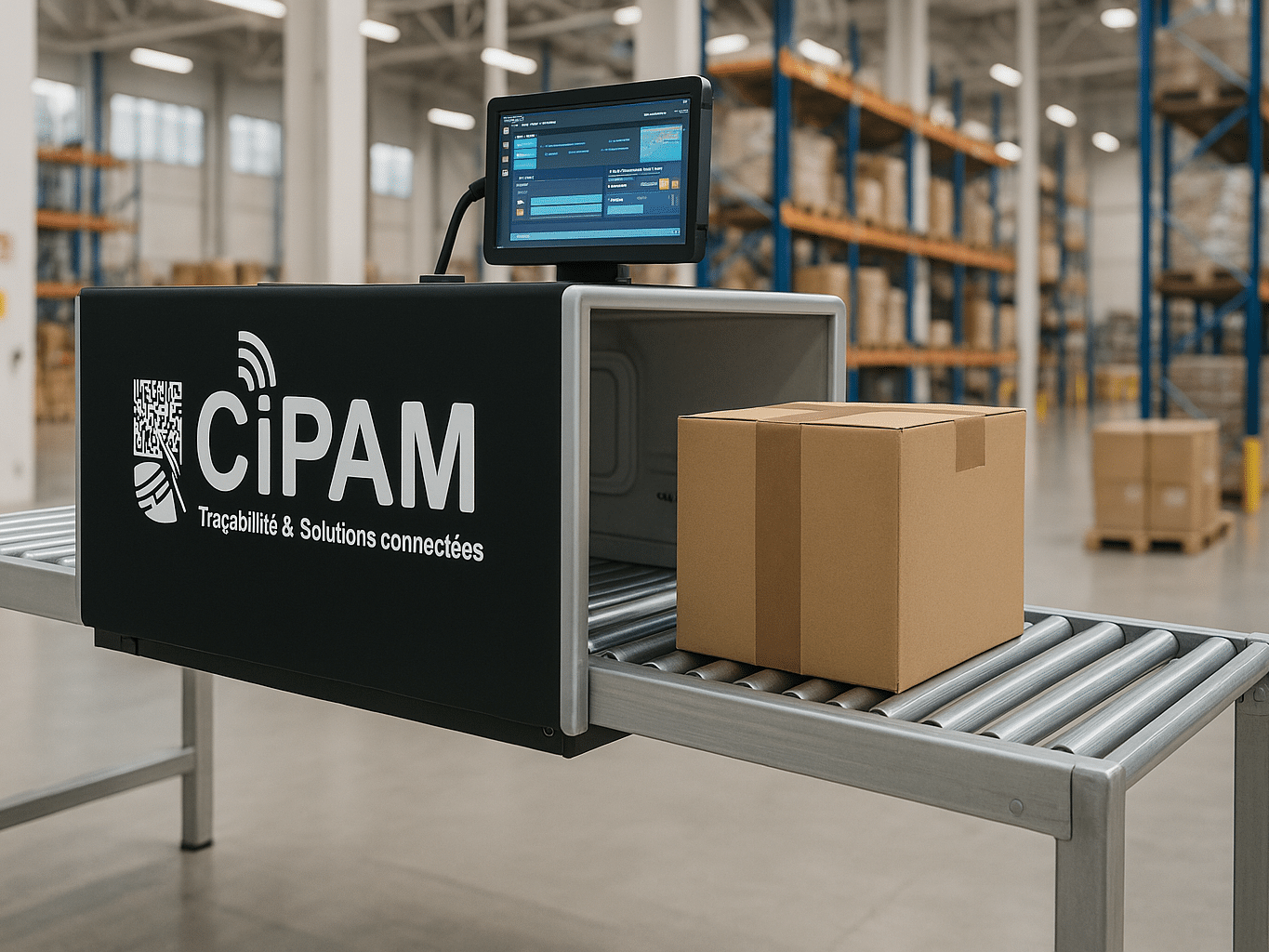

To manage your operations effectively, it's essential to collect reliable, accurate data at the right time. Data acquisition is the bridge between the physical world and your digital systems. At CIPAM, we deploy high-performance equipment capable of capturing information in the field, even in constrained or hostile environments.

Rugged industrial readers, mobile terminals, PDAs, vision cameras, RFID tunnels or gates, IoT sensors: each solution is selected and calibrated to adapt to your flows, production constraints and business requirements. The aim: automatic data capture, with no re-keying, no gaps, and immediately usable for control, traceability or decision-making.

Thanks to this intelligent data capture, you can eliminate manual errors, reduce wasted time and improve your teams' responsiveness.

Adding value to data

Industrial data has no value unless it is exploited. Too often under-utilized or dispersed, it can become a powerful lever for performance, responsiveness and decision-making. At CIPAM, we help you to structure, cross-reference and visualize this data, so as to draw concrete, actionable lessons from it.

Thanks to tailor-made software platforms, interactive dashboards and connected business applications, we transform your field data into clear indicators, intelligent alerts or automated reports. This gives you a real-time view of your flows, non-conformities, production cycles or critical equipment.

This information enhancement enables you to improve quality, anticipate deviations, facilitate audits and continuously optimize your processes.

Integrate your existing environments

In the industrial world, data is often compartmentalized between multiple tools: ERP, MES, CMMS, WMS, CRM, IoT, etc. For the digitalization of your processes to have a real impact, it's essential to connect these systems and make them interact seamlessly. At CIPAM, we design interconnected architectures that automate information flows, centralize data and guarantee consistency.

Thanks to our connectors, APIs and customized modules, we ensure total interoperability between your field tools (readers, sensors, industrial equipment) and your business software. This eliminates double data entry, reduces human error, and saves you time, reliability and visibility.

This interconnection enables you not only to optimize your day-to-day operations, but also to feed your supervision, BI or decision-support tools in a continuous, structured way.

Follow-up, support and maintenance

Setting up a traceability or automation system doesn't end with its deployment. To guarantee the durability, reliability and scalability of your solutions over time, quality support is essential. At CIPAM, we place customer care, maintenance and technical support at the heart of our approach.

From user training and preventive maintenance to responsive technical support and software upgrades, we're with you every step of the way, for the long term. We offer tailor-made contracts, adapted to your industrial constraints, with clear service commitments.

Our aim is to guarantee the availability of your tools, anticipate breakdowns, ensure that your systems evolve in line with your needs, and maximize the return on investment of each solution deployed.

Turnkey solutions

Drawing on our 30 years of expertise and customer feedback, we have developed proven turnkey solutions.With reduced adaptation requirements and predictable pricing, generate ROI quickly.With our subscription, financing or leasing solutions, simply optimize your processes.