Why traceability is essential in modern industry

Traceability is much more than a regulatory obligation: it's a lever for performance, safety and responsiveness. It enables you to know, in real time or retrospectively, where your products are, what events they have been through, and how your processes can be improved.

At CIPAM, we design automated traceability systems adapted to your industrial constraints: sensitive sites, high production rates, regulatory requirements, multi-site management, etc.

Automated traceability and contactless reading

Identification is only of value if it is correctly read and used. Our automated traceability solutions are based on real-time data capture through various devices.

10-fold reduction in quality control time, fewer non-conformities, greater inventory accuracy.

Need a customized traceability system?

Let’s discuss your needs

Intervention anywhere in France and Europe

Mobile or industrial readers

Robust equipment to capture data where it's needed

- Ruggedized RFID or barcode scanners

- Online or offline mode

- Ergonomic field input

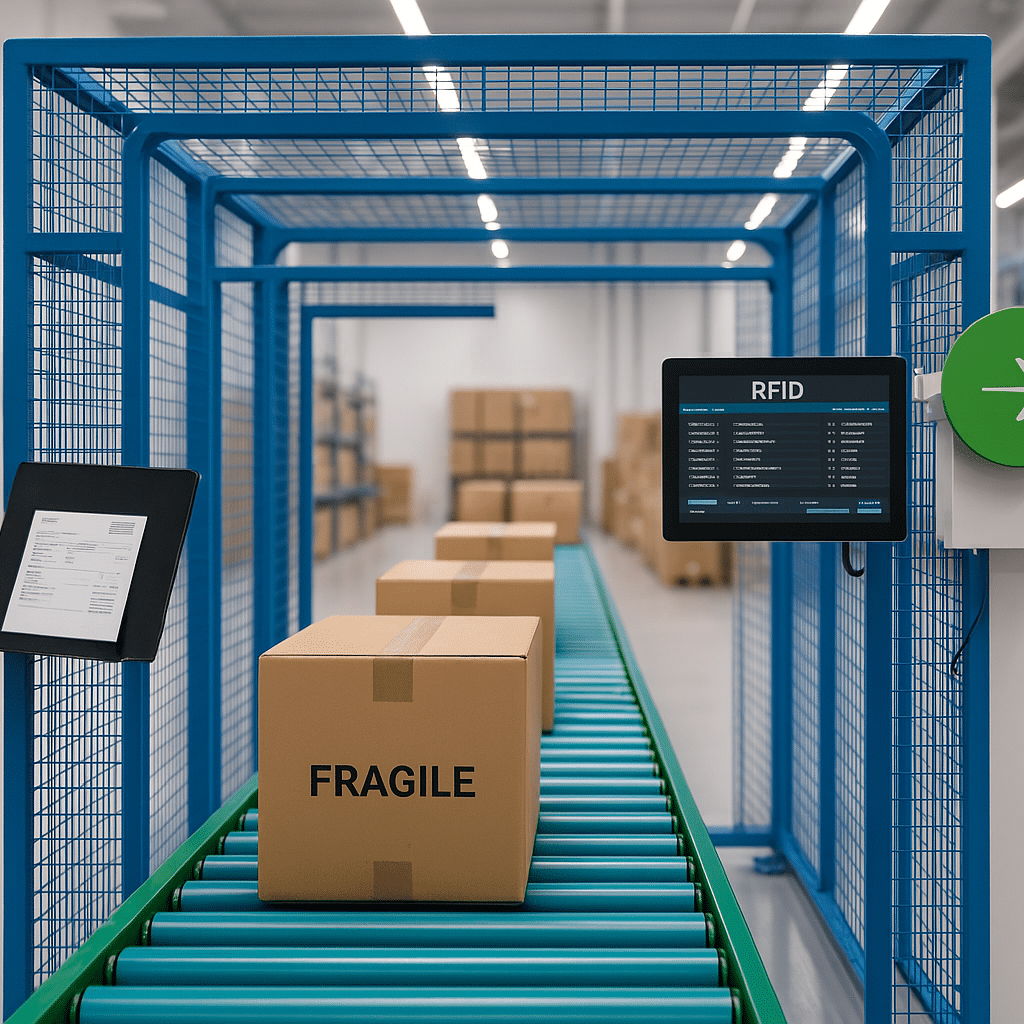

RFID tunnels and gates

Speed and reliability

- Automatic counting of incoming/outgoing products

- Simultaneous reading of dozens of labels

- Integration with ERP or WMS

Connected sensors (IoT)

Adaptable solutions, whatever your context

- Real-time monitoring: temperature, humidity, position, status

- Connectivity BLE, LoRa, Wifi, GSM

- Automatic alerts when thresholds are exceeded

Industrial vision

Machine vision automates visual quality control at high speed. CIPAM integrates intelligent cameras to check markings, read codes (OCR/2D), detect anomalies or missing labels, thus guaranteeing conformity without slowing down production.

- Automated optical reading of codes or markings

- On-board quality control

- Adaptable to production lines

Expertise

Compliant, usable and integrated traceability

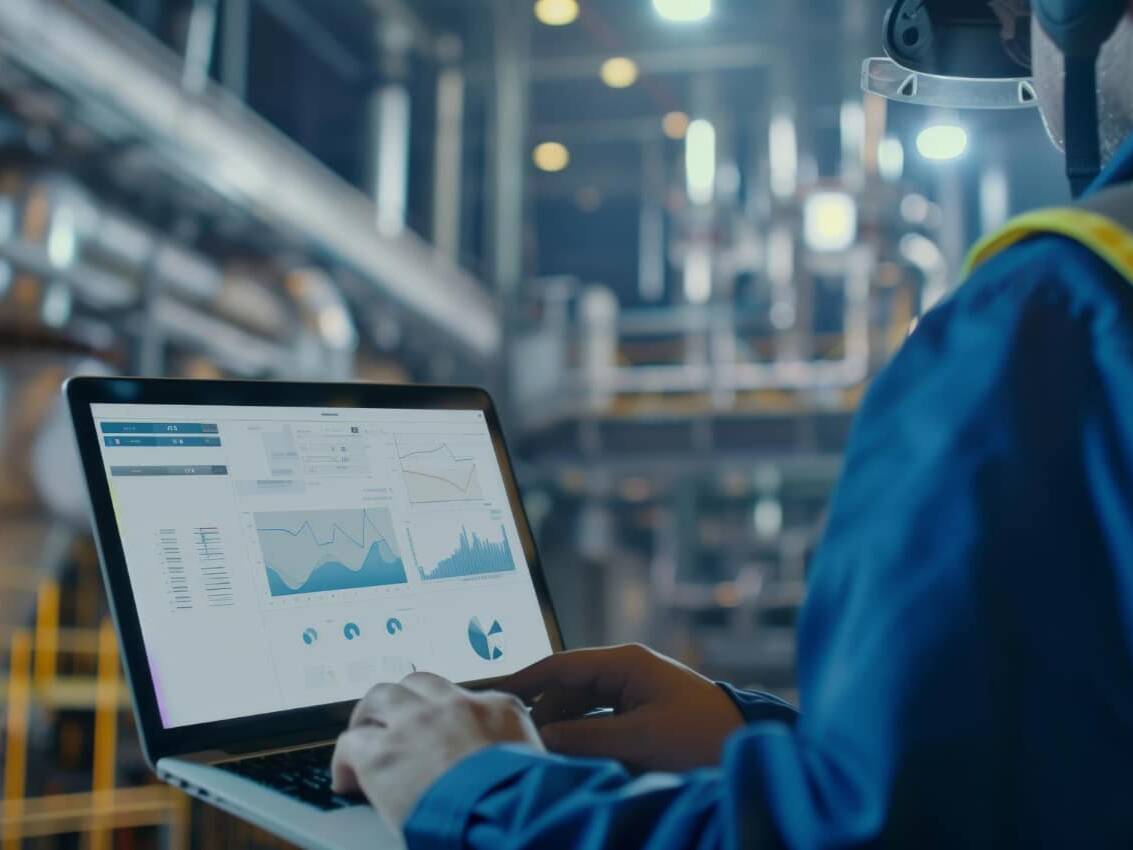

We can help you set up a complete traceability chain, interconnected with your existing systems.

Reduced audit preparation time, centralized data, zero traceability gaps.

Interfacing with your tools

ERP (SAP, Sage, Cegid, etc.), WMS, MES, CMMS<br>-Data synchronization and workflow automation

Intelligent data processing

- Customized dashboards<br>- Traceability break alerts<br>- Automated audit reports

Compliance with industry standards

- 21 CFR Part 11 (pharma)<br>- ID Rail (rail)<br>- GS1 / UDI / ISO / FDA standards

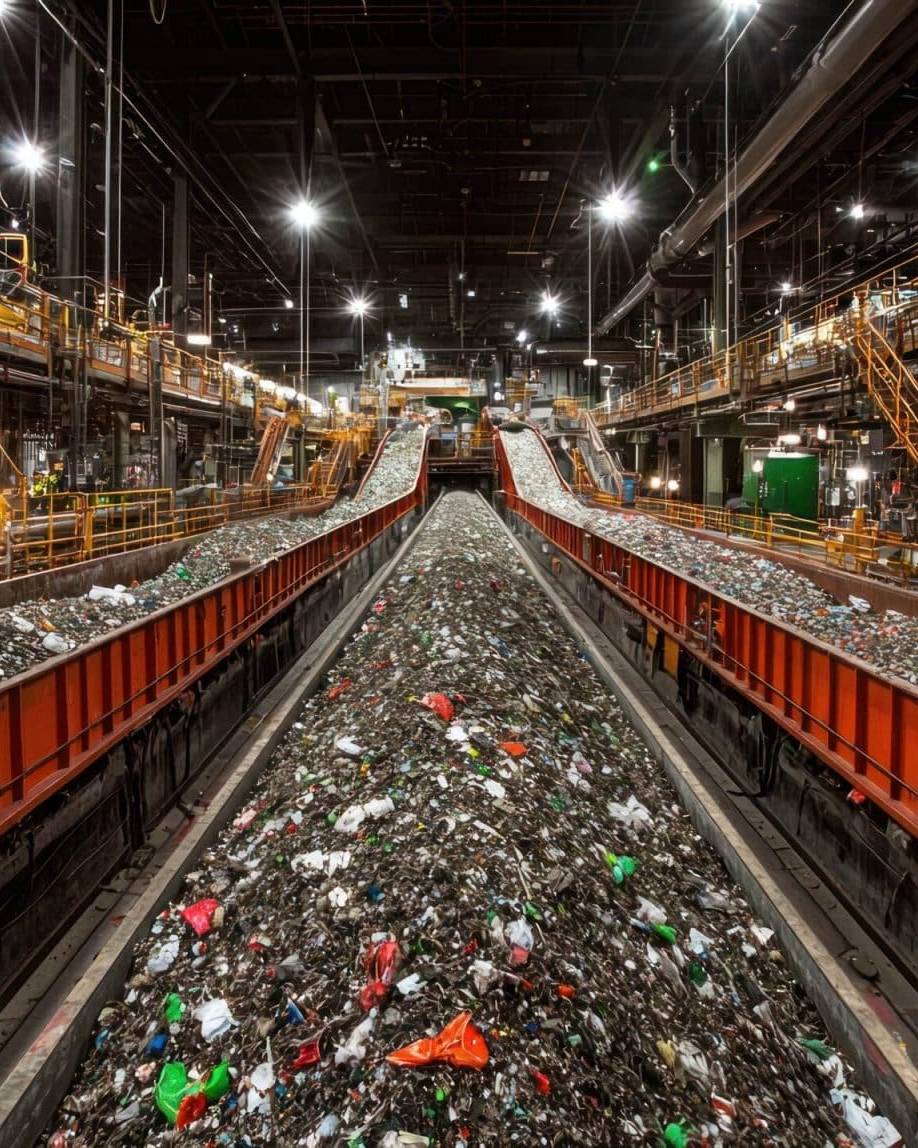

Concrete applications by sector

Why choose CIPAM?

30+ years' experience in the field

Over 400 sites equipped in France and Europe

A global approach: audit, equipment, software, integration

Long-term support (maintenance, upgrades, support)

A clear objective: to help you make the most of every solution deployed

Ongoing technology watch

Need a customized traceability system?

Let’s discuss your needs

Intervention anywhere in France and Europe