Why has traceability become a strategic function?

In an increasingly automated, regulated and interconnected industrial environment, the ability to identify and track each product, asset or person in real time has become a major driver of performance and safety.

At CIPAM, we support you in the implementation of intelligent traceability systems, adapted to your business constraints, regulatory requirements and operational objectives.

Our approach is based on two pillars:

Reliable, durable identification adapted to the environment

Automated, interconnected data collection

Our industrial identification solutions

Every project starts with a technological choice adapted to your field reality. We help you select the right substrates, in the right format, with the right level of durability, taking into account your process and constraints (heat, abrasion, ATEX environment, etc.).

Eliminates data entry errors, saves time in production, improves traceability for audits.

Industrial labelling

Reliable even in the most demanding environments

- Barcodes, 2D codes, QR codes

- Paper, synthetic or metal labels

- Resistant to heat, humidity and solvents

RFID (radio frequency identification)

Performance, durability and guaranteed return on investment

- Passive, active, hardened labels

- Non-contact, mass, moving reading

- Rewritable and traceable over several cycles

Direct part marking (DPM) and laser marking

Lifetime traceability of your critical parts

- Direct marking on metal, plastic or glass

- Unalterable, permanent, compliant with industrial standards

- Compatible with machine vision or portable readers

Expertise

Compliant, usable and integrated traceability

We can help you set up a complete traceability chain, interconnected with your existing systems.

Reduced audit preparation time, centralized data, zero traceability gaps.

Need a customized traceability system?

Let’s discuss your needs

Intervention anywhere in France and Europe

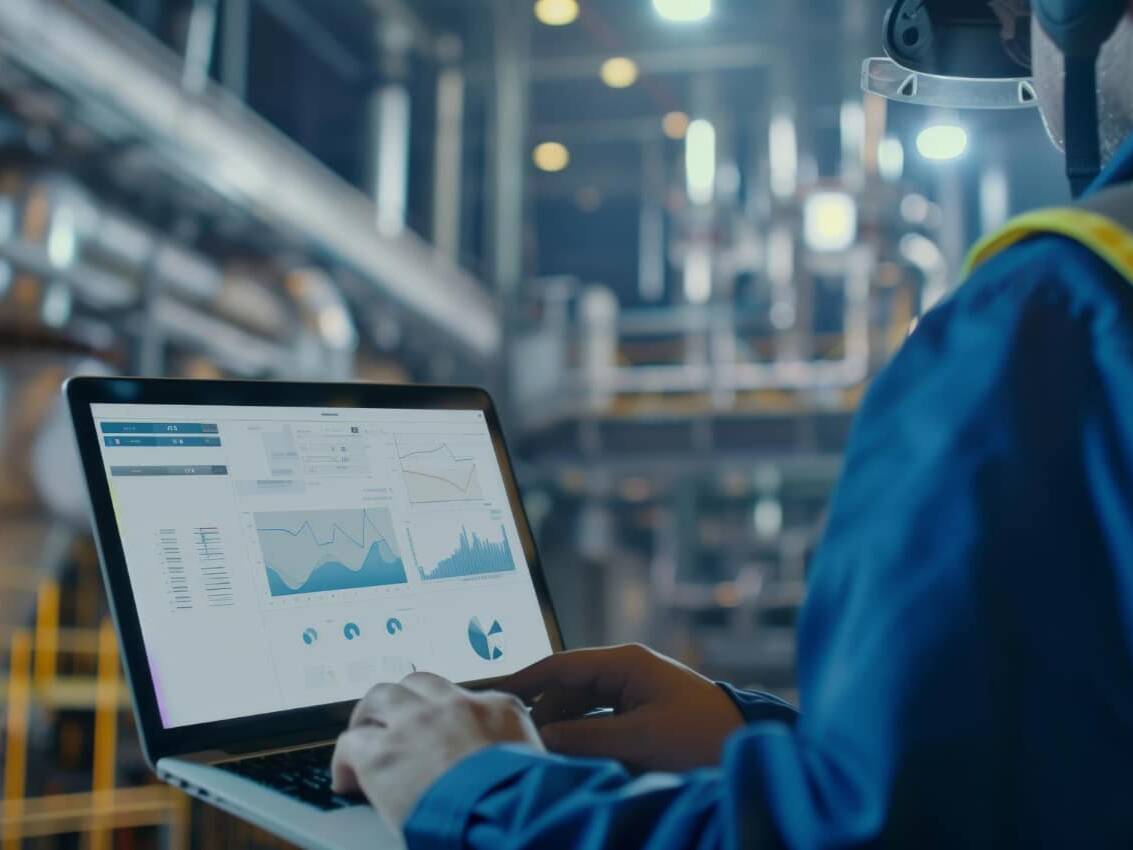

Interfacing with your tools

ERP (SAP, Sage, Cegid, etc.), WMS, MES, CMMS<br>-Data synchronization and workflow automation

Intelligent data processing

- Customized dashboards<br>- Traceability break alerts<br>- Automated audit reports

Compliance with industry standards

- 21 CFR Part 11 (pharma)<br>- ID Rail (rail)<br>- GS1 / UDI / ISO / FDA standards

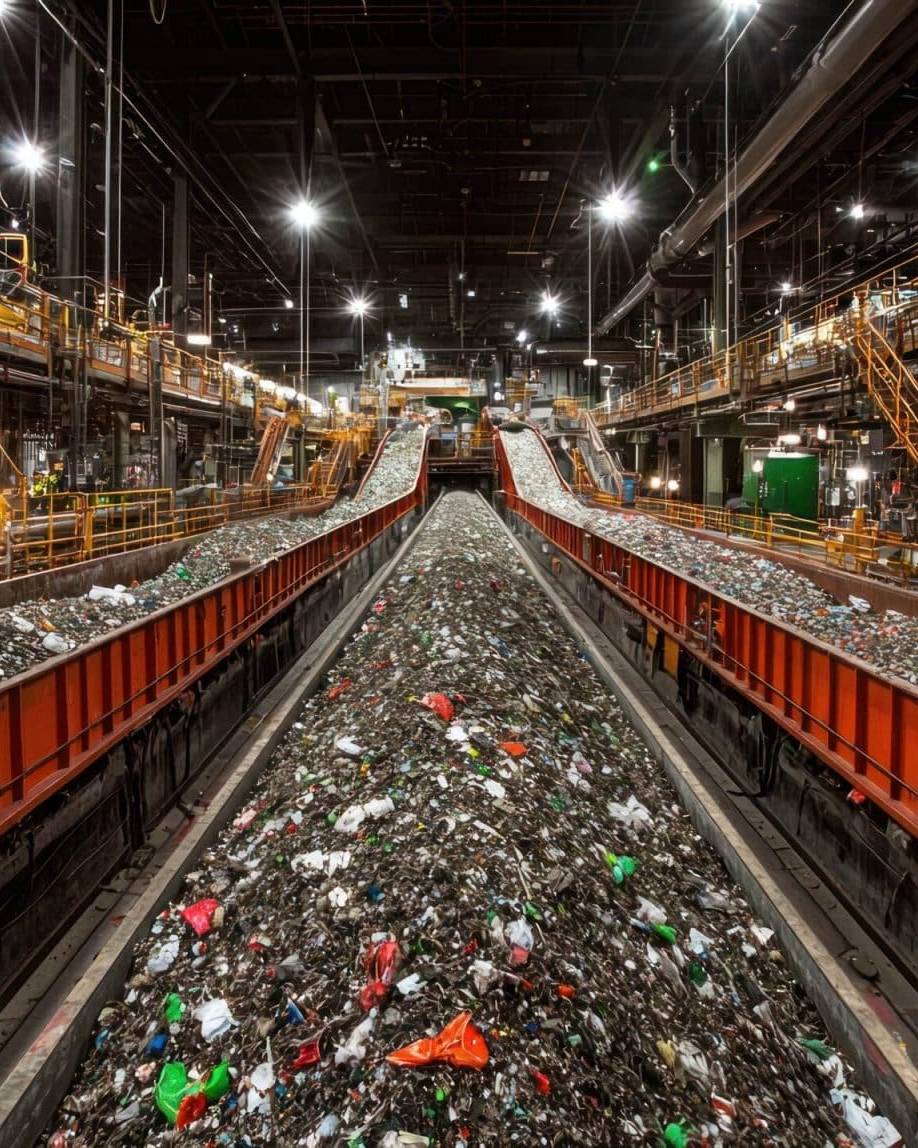

Concrete applications by sector

Why choose CIPAM?

30+ years' experience in the field

Over 400 sites equipped in France and Europe

A global approach: audit, equipment, software, integration

Long-term support (maintenance, upgrades, support)

A clear objective: to help you make the most of every solution deployed

Ongoing technology watch

Need a customized traceability system?

Let’s discuss your needs

Intervention anywhere in France and Europe