Theelectronics industry was one of the first to use direct laser direct laser marking to identify boards and PCBs reliably and securely throughout the manufacturing process.From manual and fixed DPM readers readers are installed on production lines to read low-contrast codes. Future electronic cards will be identified by RFID chip, with an RFID component intrinsic to the card.

CIPAM can intervene at all stages of traceability projects, for laser marking systems, for DPM reading tools with specific decoding algorithms and lighting, for RFID encoding tools encoding tools, as well as hardware and software solutions for inventory, search and production tracking.

Example of a realization

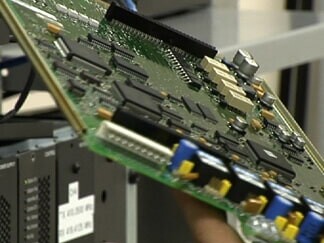

Traceability solutions for electronic components in the assembly line

- Context

In a factory producing electronic boards, certain sensitive components (MSL coils) have a very limited lifespan as soon as they leave the dehumidifying dry cabinet. What’s more, each component has to be placed very precisely by the robots on the board: a place for everything and everything in its place!

Most of the electronic components used are not manufactured in-house. The study therefore focuses on the electronic board assembly line.

- Objectives

Ensure that the right components are in the right places according to the loading plan

Automatically signal the end-of-life of MSL components.

- Solution implemented

As they enter the assembly line, each electronic component is assigned a serial number via a DATAMATRIX code printed on a label.

Each location in the picking area near the robots is also uniquely identified;

For each electronic board to be produced, there is a “recipe” which lists the precise part numbers of each electronic component and their location in the robot’s picking zone;

The operator must read the DATAMATRIX code of each component and the code of the location where it is placed in the picking zone; In the event of an error, an alert message is displayed;

Similarly, if an MSL component has been out of the dry cabinet for too long, an alert tells it to scrap it;

- Earnings

Full traceability of electronic components, right down to the serial number, with audible and visual alerts, ensures that the right component has been placed in the right place on a specific circuit board.

The exposure time of moisture-sensitive components (MSL coils) is clearly monitored to guarantee the quality of the final product.

- Services/Supplies

- Study and design of the solution

- ZEBRA wifi PDA, thermal transfer printer, rugged tablets

- MySql database;

- PDA Wifi communication with the remote base via the Apollo server;

Would you like to find out more about our solutions?

Let’s discuss your needs

Intervention anywhere in France and Europe