The performance of an RFID solution solution depends 80% on the tag you affix to your products. Poor range, delamination, extra cost... the "wrong" choice can wipe out your ROI. For over 30 years, CIPAM has been testing, qualifying and deploying RFID tags in the most demanding environments (industry 4.0, railways, agro-logistics, FIA...). This page provides you with a proven method for selecting THE right tag - and a free audit to secure your project.

How do RFID tags work?

An RFID tag (or transponder) consists of an inlay (antenna + chip) encapsulated in a protective material. When it passes into the radio field of a reader, the antenna picks up energy(passive tag) or activates its own transmitter(active tag), the chip modulates the response, and the unique identifier is captured without contact, even out of sight.

| Tag type | Power supply | Typical range | Benefits | Limits |

|---|---|---|---|---|

| Passive (LF/HF/UHF) | Drive energy | 1 cm → 15 m | Economical, fine | Range <15 m, environment-sensitive |

| Semi-passive | µW battery for chip | 1 cm → 20 m | Better sensitivity | Battery life |

| Active (BLE, UWB, 2.4 GHz) | Integrated battery | 50 m → 200 m | Range & sensors | Cost + maintenance |

To remember: 85% of industrial projects rely on passive UHF (EPC Gen2) for its performance/price ratio.

Key parameters for choosing your label

Frequency & regulations

- LF 125 kHz / HF 13.56 MHz: reading in liquids or thick metal, short range.

- UHF 860-960 MHz: speed & range, ideal for the supply-chain. Beware of regional bands (ETSI vs FCC).

Substrate & form-factor

- Wet inlay, dry inlay, paper label, on-metal label, ABS hard tag, nail-on tag, zip-tie cables… your substrate determines the mechanics and cost.

Environmental conditions

- Temperature: -40°C to +250°C (paint process, autoclave)

- Chemicals & solvents: selection of specific encapsulants (PA6, Peek, PPS)

- Metal & liquids: insulated antenna or “on-metal” label with ground plan.

Reading range & density

- Number of simultaneous tags, conveyor speed, orientation. CIPAM tests validate radio margin.

Standards & certifications

- GS1 EPC Gen2, ATEX, ID-Rail, IATA… CIPAM ensures compliance and serialization throughout the chain.

CIPAM method: 5 steps to make your selection more reliable

- Process & constraints analysis Process analysis: field audit + flow mapping.

- Constraint matrix ↔ tags : pre-selection of references from >2,000 catalog tags.

- Tests: climatic cycles, abrasion, range, EPC/USER memory.

- On-site pilot Sample batch, reading KPIs, operator feedback.

- Deployment & framework contracts Consolidated logistics, printing/encoding, maintenance.

Need help choosing your RFID tags?

Let’s discuss your needs

Intervention anywhere in France and Europe

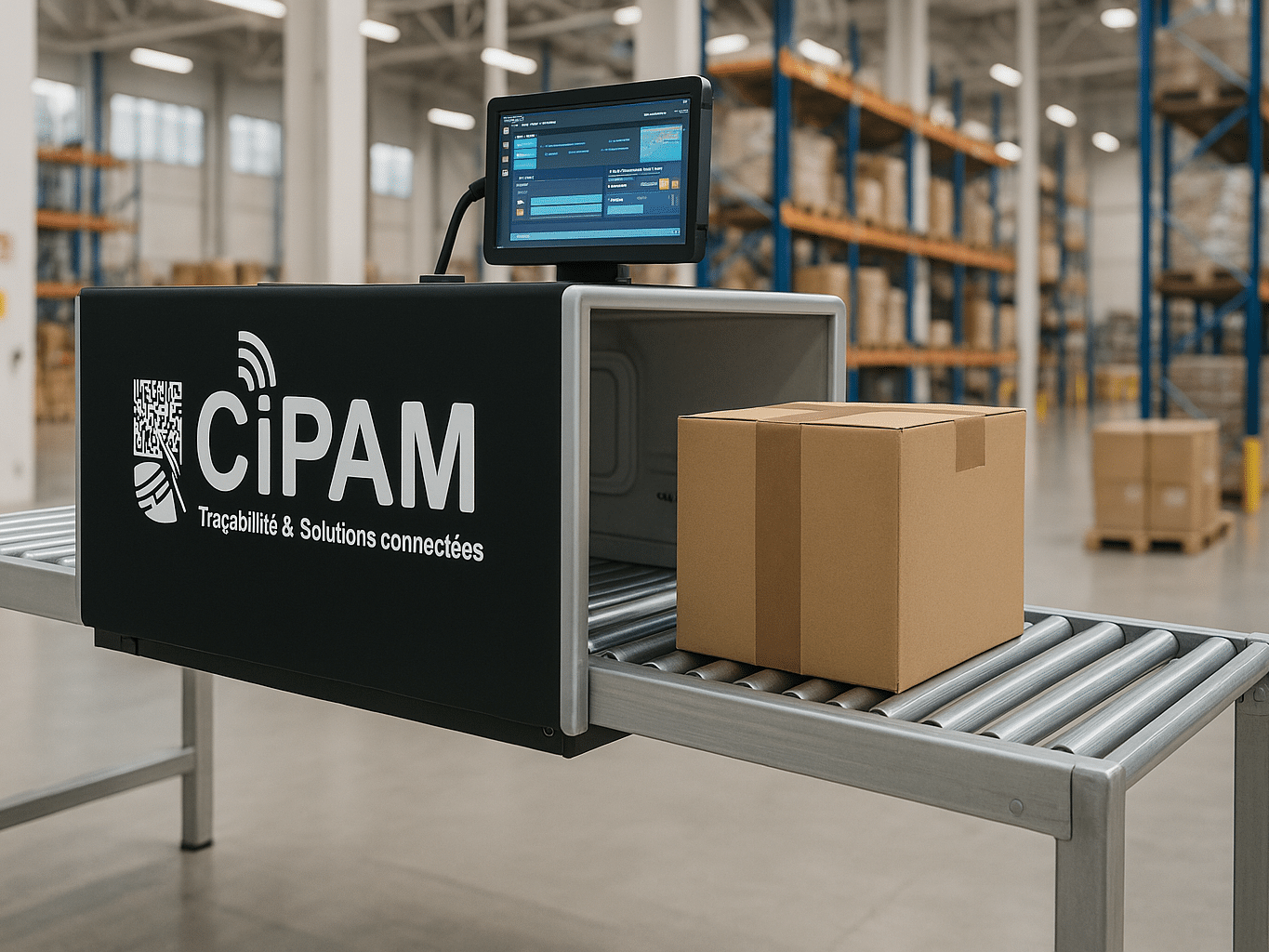

Shipment control: RFID tunnel

A logistics site reduced inspection times by a factor of 20 by palletizing paper UHF tags on stretch film and reading 200+ tags in <3 s in our RFID Tunnel. Zero errors, ROI <9 months.

FIA competition tires

Peek encapsulated high-temperature UHF tags, resistant to +200°C and 2 bar deformation. Reliable pit-lane reading at 12 m, even in humid conditions.

Forklift location

Combination of UHF tag + active BLE tag for geolocating warehouse carts to an accuracy of <1 m. Reduces downtime by 15%.

Would you like to find out more about our solutions?

Let’s discuss your needs

Intervention anywhere in France and Europe

Faq

Frequently asked questions about RFID tags

20 years+ in storage, >200,000 read/write cycles.

Yes, CIPAM offers printer-encoders and a labeling office service.

Most UHF inlays use aluminum and a PET substrate; CIPAM is investigating paper and biodegradable copper options for the digital product passport.

AES-128 protocol, locked TID, kill command: CIPAM configures your tags to prevent copying.

From €0.03 (UHF volume inlay) to €15 (ATEX active hard-tag). We optimize TCO (Total Cost of Ownership) via framework contracts.