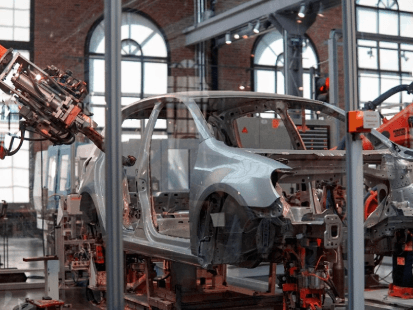

In all automotive manufacturing processes, there is a constant need to improve productivity and profitability.Traceability must make it possible to consolidate all manufacturing information, and relies on both manual and automated systems: from direct printing or labeling, to data reading or recognition.

CIPAM can intervene in all stages of projects: from the laser marking systemmarking system, for direct part identification, to reading tools, including asset management and geolocation systems.

Example of a realization

Automated tire monitoring and control solutions for racing tires

- Context

Car racing – rallying, FIA, endurance racing – requires the use of tires to be checked and controlled.

- Objective

Automatically detect tyres and determine their position at 60km/h.

- Solution implemented

The tires are fitted with RFID chips. As the race cars pass through the gantries, designed and developed by CIPAM, the RFID chips are read and the data instantly transmitted to the control computers. In this way, frauds, set-up errors and other problems are directly identified and corrected.

- Earnings

- Full traceability

- Automatic control

- Reduce costs and process times

- Real-time data

- Possible developments

- Services provided by CIPAM

- Feasibility study

- Prototyping

- Software development

- Training & Maintenance

Fleet vehicle tracking and management system

- Context

A major car manufacturer has to manage tens of thousands of vehicles in its fleet, i.e. locate one vehicle among thousands of identical ones, know which products make up the stock and where they are in the supply chain.

- Objective

Develop a system to reduce product delivery delays and excessive or obsolete inventory, as well as to locate specific parts and vehicles.

- Solution implemented

A vehicle tracking and management system (VTMS) application has been implemented. This provides constant visibility and management of vehicles, from final assembly to shipment, making it easy to instantly locate specific vehicles to meet customized dealer orders, or to identify vehicles waiting for quality control.

- Earnings

- Savings on installation costs

- Quick installation with an online call system in just a few weeks

- Proven reliability and performance

- Reduced waiting time for vehicles in the field by at least one day;

- Services/Supplies

- Vehicle tracking and management system (VTMS)

- Wireless replenishment

- WherePort

- WhereLan

- WhereCall

Would you like to find out more about our solutions?

Let’s discuss your needs

Intervention anywhere in France and Europe