Why RFID traceability is essential in modern industry

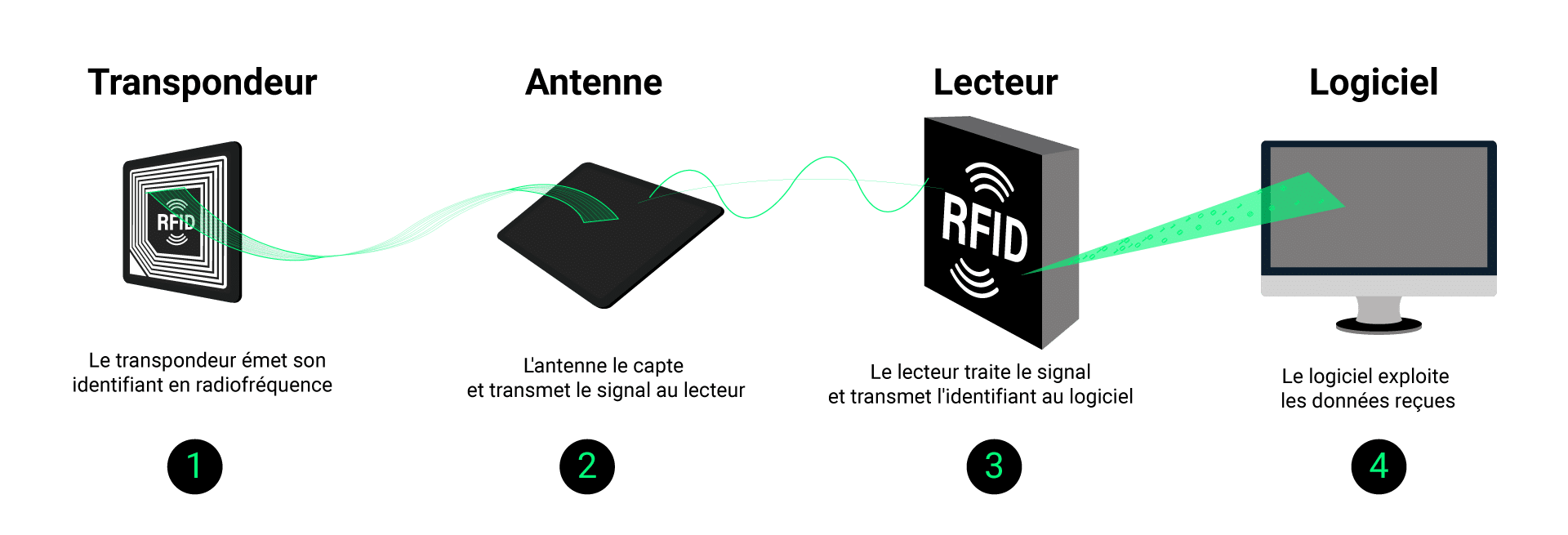

RFID (Radio Frequency Identification) traceability enables products, containers, tools or equipment to be identified and tracked without contact, and often by mass reading. Where barcodes require individual targeting and reading, RFID automates collection and reduces dependence on operator gestures – a direct lever on reliability, inspection times and disputes. To understand the principles (UHF/HF, tags, range, constraints), consult our page RFID technology.

At CIPAM, we combine two indispensable dimensions:

- supply of equipment(tags/labels, readers, antennas, RFID printers),

- the creation and integration of solutions(tunnels, gantries/totems, automation, IS connectors) to transform RFID readings into usable business events.

In 30 seconds: Why CIPAM RFID traceability?

- You can automate proofing: shipping, receiving, zone entry/exit, inventory, WIP – without relying on manual scans.

- You get reliable business events: filtering/duplication + “expected vs. read” rules + time-stamped proof + ERP/WMS/MES integration.

- You secure a rapid ROI: fewer errors, shorter inspection times, more reliable stock (e.g. Limagrain Europe: inspection ×30, ROI 9 months; CNAV: 1-day inventory → 10 minutes).

Contents

- What’s the point of RFID traceability (really)?

- A successful RFID traceability solution = hardware + engineering + software

- How CIPAM structures your RFID traceability project

- ROI, proof and results: what RFID traceability means in practice

- RFID traceability use cases by industry: concrete scenarios, points of truth, expected benefits

- FAQ : RFID traceability

What's the point of RFID traceability (really)?

RFID becomes particularly profitable when it tackles recurring operational problems:

- Shipping/receiving control: automatically check the contents of a parcel, crate or pallet.

- Stocks & inventories: speed up inventories, improve position reliability, reduce discrepancies.

- WIP / production: trace progress, avoid shift errors, secure batches.

- Assets & tooling: unambiguous identification, faster retrieval, reduced losses and downtime.

The value is not “the RFID reading”, it’s the decision triggered: OK compliance, deviation alert, blocking, print restart, ERP/WMS update, etc.

A successful RFID traceability solution = hardware + engineering + software

1) Hardware components (what CIPAM supplies and integrates)

- RFID tags / labels adapted to your requirements (metal, temperature, chemistry, abrasion, IP, etc.).

- Readers & antennas (fixed, mobile) sized according to area, data rate, distance and radio environment.

- RFID printers (encoding + printing) to industrialize identification right from the label.

2) Automatic stations (where RFID creates a "point of truth")

- RFID tunnel: automatic mass reading for package/case/pallet control, as a stand-alone station or integrated into the logistics line.

- Gantry / Totem RFID: reliable detection at the entrance/exit of an area (workshop, airlock, dock), without manual scanning.

See our RFID Tunnel

See our RFID Gate

Find out about portal and tunnel feedback

3) Software and SI integration (what transforms signal into result)

Without software, RFID remains “radio noise”. Middleware and business rules enable: filtering/duplication, events (input/output, compliance, status), time-stamping, traceability, and connection to your tools (ERP/WMS/MES/GMAO).

How CIPAM structures your RFID traceability project

1. Identify assets and flows

We qualify: objects to be traced, logistical units, reading points, criticality, field constraints, expected levels of proof.

2. Data acquisition (RFID, terminals, gantries, tunnels)

We choose the right acquisition method: unitary vs. mass reading, fixed vs. mobile, controlled zone, passage speed, robustness.

3. Add value to data (events, KPIs, dashboards)

We transform readings into actionable information: compliance, status, anomalies, performance, audit traceability.

4. Integrate your existing environments (ERP/MES/WMS/GMAO)

CIPAM connects field equipment to the IS via API/real-time exchanges, eliminating re-entry and gray areas.

5. Follow-up, support, maintenance (sustainability, MCO, financing)

We provide you with long-term support, maintenance, upgrades and CAPEX/OPEX options.

ROI, proof and results: what RFID traceability means in practice

RFID becomes profitable when it transforms a costly and fragile control into an automatic, fast and proven process. The ROI is not based on “reading RFID”: it’s based on eliminating errors, reducing inspection times, making stock more reliable and reducing disputes.

At CIPAM, we measure performance using simple operational KPIs:

- compliance “expected vs. read” (shipping / receiving)

- inspection time and inventory time

- data reliability (discrepancies / anomalies)

- direct savings (errors avoided, operator time recovered)

- payback period

Three field results that illustrate ROI

CNAV – IT asset management (RFID portal)

- Pre-inventory: 1 day

- Inventory now: 10 minutes

- Verbatim: ” We managed to save hours and hours of work “.

- Associated benefits: time savings, more reliable flows, real-time traceability, instantaneous data.

SPAMER – Food processing / logistics (RFID shipping control)

- 100% conformity of delivered pallets

- 90% time saving vs. manual barcode inspection

- 100% stock reliability, customer satisfaction

- Reducing shift fatigue.

Limagrain Europe – Agro / logistics (RFID tunnel, package/box control)

- Control time: 7 minutes → 14 seconds per box(×30)

- Reliability: > 99.9% (1 fault per 1,000 cartons)

- Operator savings: 338 hours/year reallocated to value-added tasks

- Errors avoided: €18,000 from the first campaign

- ROI: investment amortized in 9 months

- Testimonial: Yann Montavy, Logistics Manager.

Why these ROIs are achieved (the mechanics behind the figures)

These gains appear when RFID is deployed as a point of truth connected to the IS:

- automated reading (portal/tunnel)

- reliability (filtering, deduplication, zone control)

- business rules (expected vs. read, exceptions, blocking/alerting)

- time-stamped event (proof)

- ERP/WMS/MES update (removal of gray areas)

Need an RFID traceability system?

Let’s discuss your needs: flows, radio constraints, IS integration, ROI estimates…

Intervention anywhere in France and Europe

RFID traceability use cases by industry: concrete scenarios, points of truth, expected benefits

RFID use cases vary from sector to sector (objects, constraints, cadence, proof requirements). The blocks below give a direct reading: where to place the point of truth, what to automate, what gains to expect.

RFID traceability for logistics and warehousing: dispute-free shipping/receiving, more reliable inventory

Objective: transform shipping and receiving into “proven”, fast, reproducible processes.

Typical points of truth

- control of preparation output (case/carton),

- pallet,

- dock exit,

- reception desk.

What RFID automates

- expected vs. read” compliance,

- immediate alerts in case of deviation,

- history of shipping/receiving events,

- faster, more frequent inventories,

- traceability of reusable containers.

Expected benefits

- drastic reduction in errors and disputes,

- reduced inspection time,

- more reliable inventory (fewer discrepancies),

- reduced drudgery (fewer scans, less handling).

Field references:

- SPAMER (food processing / logistics): 100% pallet compliance, 90% time saved, 100% stock reliability.

- Limagrain Europe (agro / logistics): 7 min → 14 sec, reliability > 99.9%, ROI 9 months.

Agri-food: conformity, cadence, flow traceability, reduction of deviations

The aim is to ensure the reliability of high-speed flows, where errors quickly have repercussions in terms of quality, returns, penalties and image.

Typical points of truth

- line output / end of packaging,

- consolidation / palletizing,

- shipping,

- container management (bins, racks, pallets).

What RFID brings

- proof of delivery control,

- reduced operator variability,

- tracking of internal movements (zones, status),

- improved stock reliability.

Expected benefits

- reduction in claims,

- faster shipping,

- customer satisfaction,

- lower inventory variances.

RFID traceability in the manufacturing industry: OF, workshop flows, quality, shift errors

Objective: secure manufacturing progress and status, reduce errors discovered too late.

Typical points of truth

- station input/output,

- entrance/exit waiting areas,

- inter-workshop movements,

- control kits/components.

High-value RFID scenarios

- WIP events (zone passage, status),

- securing batches and series,

- reduction of shift errors (wrong container, wrong route),

- traceability of tooling and assets.

Expected benefits

- fewer reworks,

- better quality traceability,

- more reliable management (events vs. declarations),

- better availability of assets/tools.

Chemicals: traceability of containers (IBCs, drums, totes), rotations, compliance

Objective: make container traceability reliable in constrained and often multi-actor environments: location, status, rotation, compliance, proof.

Containers concerned

- IBCs, drums, totes, containers, crates, specific pallets,

- returnable or reusable containers,

- containers associated with batches, statuses, zones.

Typical points of truth

- storage area entry/exit,

- in/out workshop/production,

- quarantine / waiting areas,

- shipping/receiving output.

Frequent constraints

- aggressive environments (chemicals, abrasion, humidity, cleaning),

- need robust tags (hardened, encapsulated) and suitable fasteners,

- audit and proof requirements.

What RFID can do

- unambiguously identify a container (even in mass readings),

- automatically track movements (zone entry/exit) and status (available, waiting, in progress, shipped, received),

- reduce losses and “untraceable” containers,

- accelerate inventories and controls,

- reinforce compliance (time-stamped proof, historical record).

Expected benefits

- reduction in container fleet gaps,

- improved rotation and availability,

- fewer manual searches and retrievals,

- improved audit quality (reliable, traceable events).

Pharmaceuticals and medical devices: batches, compliance, auditability

Objective: secure flows where proof counts as much as efficiency: batch traceability, auditability, error reduction, reliable and instantaneous data to limit quality risks and rework.

Typical objects to trace

- logistical units: cartons, bins, pallets, reusable containers,

- batches and sub-batches, series, status (released / quarantined / blocked),

- critical equipment or media (depending on use).

Typical points of truth

- zone entry/exit (reception, storage, preparation, production, dispatch),

- airlocks / controlled zones (mandatory passage, record keeping),

- consolidation items (creation of orders/shipping),

- quarantine zones (status and movements).

High-value RFID scenarios

- Event-based batch traceability: each passage creates a time-stamped event (zone entry, zone exit, status change), which can be processed in the IS.

- Expected vs. read” shipping control: automatic validation of parcels/pallets before departure to reduce errors and disputes.

- Status governance: RFID is used to “lock” a status (e.g.: batch in quarantine) by providing evidence of an event, and to trigger an IS action.

- Industrialized RFID labeling: printing/encoding with serialization, encoding control, label traceability (and object ↔ ID link).

Frequent constraints (and project responses)

- proof requirements: time-stamping, archiving, auditing,

- risk of costly errors: need for strict business rules (exceptions, blocking, proofreading),

- varied environments: choice of tags and reading architecture adapted to the terrain,

- IS integration: feed business events, not raw readings.

Expected benefits

- reduction in preparation/shipping discrepancies and errors,

- improved auditability (time-stamped proof),

- better control of statuses (quarantine, release, blocking),

- fewer operations and re-entries, saving time and reducing drudgery

Aerospace and defense: critical assets/tooling, sensitive areas, evidence

Objective: guarantee the availability and conformity of critical assets (tooling, equipment, kits) and secure movements in sensitive areas with robust proof. In these environments, an error does not cost “just time”: it can cost a shutdown, a major rework, or a non-conformity that is difficult to justify.

Typical objects to trace

- specialized tools, measuring instruments, critical equipment,

- component kits, dedicated containers, technical bins/suitcases,

- mobile assets (carts, racks, supports) according to context.

Typical points of truth

- workshop entry/exit (tool movements),

- passage through restricted/sensitive areas (airlocks, controlled access),

- asset storage areas (loans/returns, availability),

- kit preparation points (composition control).

High-value RFID scenarios

- Loan/return of assets: automatic identification at check-out and check-in, creation of “borrowed/returned” events, historical record, loss reduction.

- Kit control: “expected vs. read” validation of a kit before use or shipment, detection of omissions/errors without relying on manual scanning.

- Securing sensitive areas: RFID portal/totem as a point of truth: what passes through is traced, time-stamped and linked to the IS context.

- Rapid asset inventories: inventory tooling zones without tying up teams, improving asset reliability.

Frequent constraints (and project responses)

- material robustness: hardened tags, appropriate fastening, resistance to use,

- reliability requirements: zone control, anti-reading rules, exceptions,

- audit requirements: time-stamped proof, historical record, traceability of movements,

- integration: events (movements, status) fed into CMMS/ERP/MES according to organization.

Expected benefits

- reduced loss of tooling/assets, improved availability,

- reduction in kit composition errors,

- usable evidence for audit and compliance purposes,

- reduced friction and time wasted on “searching / checking / reconciling”.

Rail: life cycle, maintenance, multi-site, compliance requirements

Objective: to ensure reliable traceability over long cycles, with multi-site flows and compliance requirements. RFID provides proof of movement and status, useful for maintenance, interventions and asset history.

Typical objects to trace

- parts and sub-assemblies, bins, containers,

- maintenance tools, mobile equipment,

- assets moving between workshops, depots and sites.

Typical points of truth

- maintenance workshop entry/exit (movements and status),

- storage and preparation areas (availability, allocation),

- docks / inter-site transfer points (traceability of internal shipments),

- sensitive or restricted areas (proof of access / movements).

High-value RFID scenarios

- Traceability of inter-site movements: gantry/totem at passage points + IS events: dispatched, received, in transit, waiting.

- Maintenance status: “workshop in”, “workshop out”, “waiting”, “ready” events, linked to the asset/part in the IS.

- Accelerated inventories: inventory of stocks and assets without immobilizing a site, increased reliability of positions.

- Preparation control: “expected vs. read” validation on internal batches/shipments to reduce discrepancies.

Frequent constraints (and project responses)

- multi-sites and multi-actors: the need for clear statutes and unified rules,

- field ruggedness: tags adapted to mechanical and environmental constraints,

- proof requirements: time-stamping, archiving, auditability,

- IS integration: feed by events, not by readings, to avoid overload and guarantee consistency.

Expected benefits

- better visibility of assets and parts (where, when, in what status),

- reduced search time and losses,

- making inter-site transfers more reliable,

- enhanced auditability and reduced gray areas.

Why CIPAM (beyond "doing RFID")?

- Field approach: your RFID traceability must work every day, in your real-life conditions.

- Hardware + integration: a partner capable of supplying the building blocks and industrializing the solution (gantries/tunnels/printers + IS).

- Deployment method: scoping → POC → pilot → industrialization, with KPI.

- Experience: With over 30 years’ experience in RFID, CIPAM’s teams are experts in their field.

Interested in an RFID traceability system?

Let’s discuss your needs

Intervention anywhere in France and Europe

FAQ: RFID traceability

The barcode is excellent for unit reading with aiming. RFID is preferable when you need to read quickly, without contact, and/or en masse, in order to automate checks and reduce dependence on gestures.

Yes, with suitable tags (on-metal, encapsulated) and zone engineering. Field tests are still recommended.

This depends on material density, orientation, tag and reading architecture. A POC on your real objects quickly validates the expected performance.

Mastery comes from “zone design + middleware”: settings, orientation, reading windows, deduplication, thresholds, input/output logic.

The tunnel is ideal for channeled flow and mass compliance control (cartons/boxes/pallets). The gantry/totem is particularly well suited to zone entry/exit and movement logging.

Yes. Without business rules and filtering, RFID produces raw reads. With middleware + rules, RFID produces reliable, usable and auditable business events.

Yes, via industrial RFID printers (encoding + printing), with serialization, encoding control, print traceability and IS association.

The most robust integration consists of sending events (input/output, compliance, status, exception), rather than raw readings, via APIs or exchanges adapted to your IS.

Diagnosis (flows + constraints + IS) → field POC (tests and criteria) → KPI pilot → industrialization (multi-site deployment, MCO).