RFID: the complete guide to choosing, deploying and successfully implementing your project

RFID is no longer a technological “plus”: it’s an operational lever for making traceability more reliable, speeding up inventories, securing shipments and giving visibility to field teams. Yet many companies are still hesitating: which frequency to choose? which tags work on metal? how to integrate RFID with ERP or WMS? This guide brings together everything a decision-maker needs to know to understand RFID, select the right equipment and consumables, and deploy a sustainable project, without unnecessary jargon.

- RFID definition and technology overview

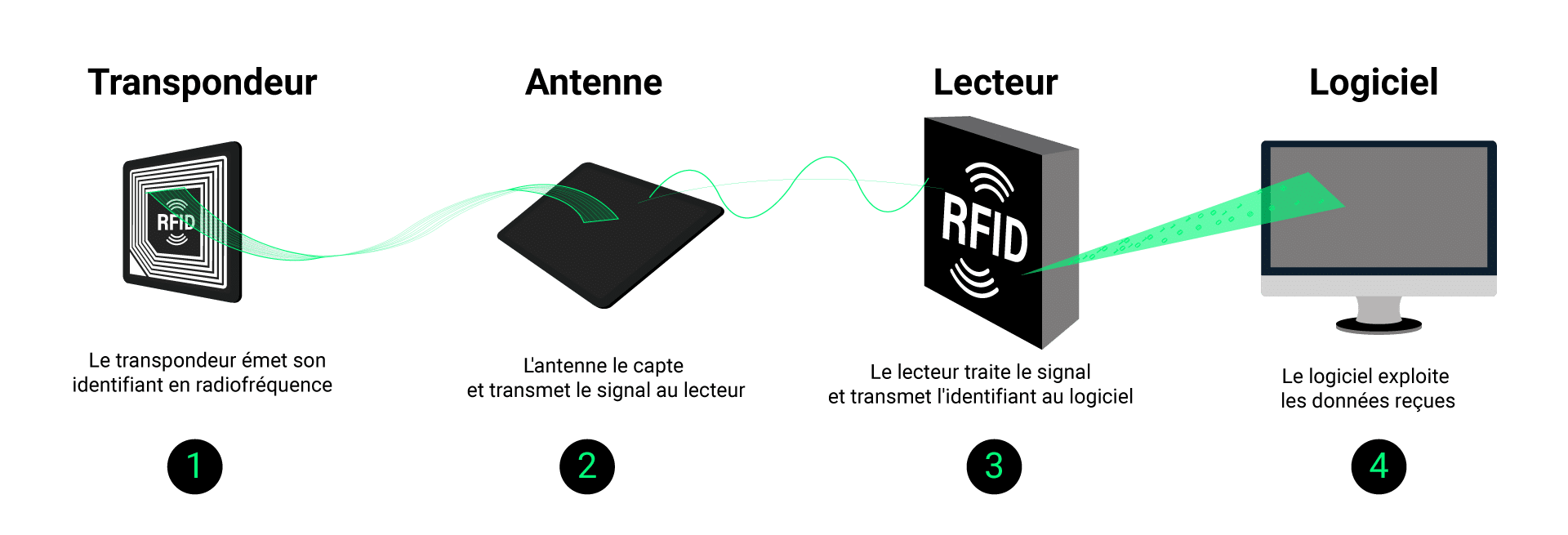

- How an RFID system works (logic diagram from signal to event)

- Components: tags, readers, antennas, printers, middleware

- Frequencies and standards: LF, HF/NFC, UHF (RAIN RFID), ETSI/FCC, EPC/ISO

- Choosing the right labels: materials, on-metal, memory, durability

- Readers & antennas: fixed, mobile, tunnels, gantries – selection criteria

- Software & IS integration: from raw flow to business event

- Advantages and limitations: what RFID does very well… and what it requires

- Concrete industrial applications: production, logistics, healthcare, agri-food, aeronautics/railways

- Deployment method: scoping → POC → pilot → industrialization

- Costs, ROI, key success factors

- RFID FAQS

1. RFID: a clear and useful definition

RFID stands for Radio Frequency Identification. In concrete terms, a reader sends out a radio wave, a tag responds with a unique identifier (and sometimes additional data), and software transforms this reading into usable information: part detected, pallet conforming, tool located, batch registered.

There are three families:

- Passive RFID: the tag has no battery and draws its power from the reader. It’s the benchmark solution for mass identification (inventories, logistics docks, WIP tracking).

- Active RFID: the tag has its own battery, offering greater ranges (several tens of meters) and specific asset supervision applications.

- Semi-passive RFID (BAP ): battery for internal electronics but reader-triggered emission; a compromise between performance and cost.

👉 Find out more about the step-by-step principles : How does an RFID system work?

2. How does an RFID system work?

Imagine a shipping tunnel Boxes pass through, several antennas create a reading volume, tags respond, middleware cleans up duplicates and validates correspondence between expected and read EPCs. If an item is missing, an alert is immediately sent to the operator.

The underlying logic is always the same:

- Transmission: the reader feeds the RF field via the antenna.

- Response: the tag receives, wakes up and sends back its identifier.

- Filtering: the software aggregates, deduplicates and time-stamps.

- Decision: the event (input, output, compliance) is produced.

- Integration: the event feeds ERP/WMS/MES, which updates inventory, OF, BL, etc.

This mechanism, simple on paper, requires skill as soon as it is confronted with the real thing: metal, water, object density, tag orientation, cadence, radio noise… This is precisely where RFID engineering makes the difference between a proof of concept and a robust solution.

Definitions :

EPC (Electronic Product Code): is a unique identifier standardized by GS1 to distinguish each object (or batch, location, container, etc.). The EPC is encoded in the RFID chip (often UHF RAIN) and read by readers to feed your systems (WMS/ERP/MES).

ERP (Enterprise Resource Planning) = global planning and management (what to produce/sell/buy, values).

WMS (Warehouse Management System) = warehouse logistics execution (where and how to move/store).

MES (Manufacturing Execution System) = production execution on the shop floor (how to produce and trace the OF).

3. The components of an RFID ecosystem

An RFID project isn’t just a pile of hardware; it’s a coherent ecosystem.

- Tags & labels: paper/plastic inlays, hard tags, on-metal tags, seals, cards, encodable thermal labels.

- Readers: mobile terminals for inventory, fixed readers for gantries, tunnels, conveyors, packaging stations.

- Antennas: polarization, gain and geometry determine the reading “bubble”.

- RFID printers: print + encode in a single pass, check for failure and retry.

- Middleware & connectors: filter, standardize and publish business events to your IS.

👉Detail by brick: RFID tags

4. Frequencies and standards: LF, HF/NFC, UHF (RAIN RFID)

Frequency determines range, speed and environmental tolerance.

- LF (125-134 kHz): short range, low sensitivity to water/metal, single reading. Applications: access control, animal identification.

- HF (13.56 MHz): includes NFC (cards, smartphones). Short to medium range, good data rates, single or small battery reading. Ideal for proximity operator routes.

- UHF (860-960 MHz) – RAIN RFID: reading at several meters, in bulk, widely used in logistics and industry. Standards: GS1 EPCglobal / ISO/IEC 18000-63 (Gen2).

Keep in mind:

- Regulations: ETSI (EU) vs. FCC (US); use compatible equipment if your traffic is international.

- Antenna and orientation: good propag’ is worth as much as the player’s power.

- Metal and water: reflections and absorptions can be controlled by tag selection and antenna design.

👉 In depth: RFID frequencies and standards

5. Choosing the right RFID tags

It’s the subject that makes a project succeed (or fail). A high-performance label on cardboard may fall apart on a metal can or a thick plastic tub. So we evaluate in the real environment:

- Format & material: paper/PP/PE/PI for consumables, hardened tags (ABS, epoxy, PBT) for reusable assets.

- On-metal: essential on metal surfaces; presence of suitable insulation or antenna structure.

- Memory: EPC/TID + any user zone; password protection, kill command in certain cases.

- Stresses: temperature, washing, sterilization, immersion, UV, shocks.

Good reflex: test several references simultaneously, changing orientation, distance, speed and object density. We’re not aiming for maximum performance in the lab, but stability in production.

6. Readers, antennas and printers: where performance counts

Clean” reading means well-placed antennas, regulated power, reduced dead zones and a controlled physical path.

- Fixed readers: gantries, shipping tunnels, checkpoints.

- Mobile readers: UHF guns for express inventories, sampling and maintenance.

- Antennas: linear vs. circular polarization, gain, angle, distance, shielding.

- RFID printers: encoding + printing with automatic verification.

Examples often favored in industrial environments: ZT411/421 RFID, RK25 UHF, SQUIX RFID. The right equipment is the one that fits your context.

7. RFID software: turning readings into decisions

Without software, RFID remains “radio noise”. Middleware transforms this noise into events:

- Filtering/duplication (to avoid multi-reading).

- Business rules (what is a valid reading? at what threshold does a non-conformity trigger?).

- Traceability (timestamp, shift, operator).

- IS connection (API, files, event queues) to ERP, WMS, MES, TMS, quality tools, etc.

Selection criteria: latency, observability (logs, metrics), standard connectors, network security and ease of administration.

👉 Panorama: RFID software: all the solutions

8. Advantages and limitations: what to expect in concrete terms

The strength of RFID lies in its contactless, mass reading. This means that workshop inventories can be carried out in minutes rather than hours, pallets can be checked automatically as they pass through a tunnel, and proof-of-reading reduces transport disputes.

Key benefits :

- Speed: flash inventories, 100% shipment control without manual handling.

- Reliability: fewer human errors, better document compliance.

- Rugged: tags and readers designed for heat, cold, dust and humidity.

- Interoperability: open standards (EPC/ISO), native IS integration.

Points to watch :

- RF environment (metal/water): to be resolved by the right tag and antenna engineering.

- Initial investment: controlled by a well-defined POC and gradual ramp-up.

Identifier governance: numbering, network security, access rules, RGPD if personal data is correlated.

9. Concrete industrial applications

Production & WIP

On an assembly line, RFID follows the part from one station to the next, locking in reference errors and providing detailed traceability of the manufacturing file. Kanban” replenishments are more responsive, non-quality is dealt with upstream, and search times are reduced.

Shipping & receiving

At the dock, an RFID tunnel automatically checks the contents of parcels/pallets: what has to go, goes; what’s missing is flagged. At receiving, anomalies are immediately visible and no longer contaminate stock.

Stocks & inventories

With a UHF terminal, you can cover an aisle in just a few minutes. A rotating inventory becomes realistic without immobilizing activity. Discrepancies are reduced, movements are better dated, and stock values are more reliable.

Health & Pharmaceuticals

Medical devices are precisely identified (sterilization, traceability of use), sensitive samples or batches are located and their logistical cycles secured.

Aerospace, rail & defense

RFID can be combined with direct part marking (DPM) for critical tooling and maintenance documentation. The aim: to know where the asset is, in what condition, and when it is due for inspection.

Food & beverage

From batch to pallet, RFID makes the “field to plate” process more reliable. Reusable containers, returnable bottles, drums: return rates improve and regulatory tracking is simplified.

👉 Course by sector: RFID in industry

10. Deployment method: from testing to deployment

A project succeeds when it is driven by usage and measured by simple KPIs.

Framing (2-4 weeks)

We map the flows, define where to read (station, passage, dock), what to decide (compliant/non-compliant), and how to integrate the data (ERP/WMS/MES). We select 2-3 tag candidates and the type of reader.

POC in real-life conditions (4-8 weeks)

We test on site, on your media, at your speed. The aim is not a record, but stability: target read rate, noise under control, middleware rules fine-tuned.

Pilot (8-12 weeks)

We switch over a significant perimeter (a line, a shipping zone), train the operators, refine the SOPs and measure: inventory time, errors avoided, disputes reduced.

Industrialization

Duplicate the recipe, standardize numbering and connectors, document (FAT/SAT, runbook), set up supervision (RF logs, alerts).

11. Costs, ROI and key success factors

Talking about figures without context would be misleading, but orders of magnitude guide the decision:

- Tags: from a few dozen cents (inlays) to a few euros (hardened/on-metal).

- Stationary readers: ~€1,500 to €4,000 excluding antennas.

- UHF terminals: ~€1,500 to €3,000 depending on robustness and options.

- RFID printers: ~€2,000 to €4,500.

- Integration: depends on IS connectors, business rules and scope.

ROI quickly becomes apparent when RFID tackles visible irritants: recurring inventories, shipping disputes, reference errors, time wasted searching. Typical gains relate to :

- Inventory time divided by 10 to 50,

- Errors and disputes down sharply,

- Enhanced operational visibility (WIP, inventory, shipping).

The keys to success: test at home, write clear business rules in the middleware, train your teams and manage the project by KPI.

Faq

Our answers to the questions often asked by our customers

The barcode requires a single sight and reading. RFID reads contactlessly and en masse, even when the visual is inaccessible. Where speed, repeatability and less human intervention are required, RFID has the edge.

NFC belongs to the HF RFID family (13.56 MHz) and targets the very short range (cards, smartphones). UHF RFID (RAIN) reads at several meters and manages dozens or even hundreds of items in a single pass: it’s the logistics/industrial standard.

Yes, provided you use on-metal tags and appropriate antenna engineering (power, polarization, orientation). On-site tests are essential to validate performance.

UHF: GS1 EPCglobal / ISO/IEC 18000-63 (Gen2). HF: ISO/IEC 14443/15693 and NFC Forum specifications. On the radio side, watch out for ETSI (EU) and FCC (US) regulations.

Yes, beyond theEPC, some chips offer user memory. Access can be protected, and some tags have akill command.

Tags from a few cents to a few euros, fixed readers from around €1,500, UHF terminals around €1,500-3,000, RFID printers €2,000-4,500. Integration costs depend on your IS and connectors.

We start with a business framework (flows, KPIs, reading points), followed by an on-site POC. We then convert to a pilot and industrialize with common rules and standards.